Standard Design Features

Below is a list of some of the key design features used in all of our pumps.

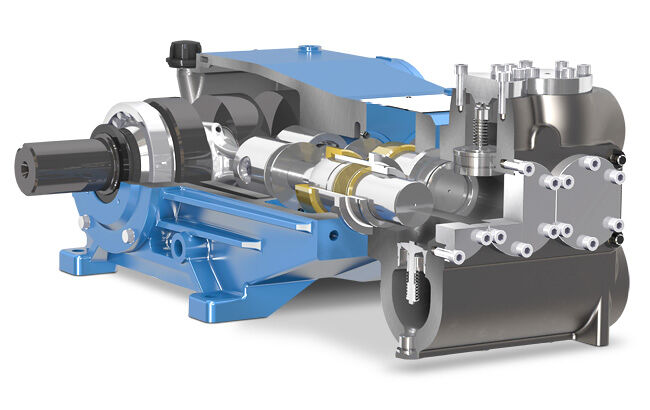

Crankcases - Crankcases are quality constructed from grey or high tensile SG iron, including low-temperature grades, depending on application and power.

Crankshafts - Crankshafts are constructed from high tensile materials suitably heat treated and processed.

Bearings - Dependent upon the application, large capacity Timken taper roller bearings or combinations of rolling element and plain bearings are used.

Lubrication - Lubrication on all models is by splash/submersion or pressure lubrication driven directly by the crankshaft of the pump. In the latter case, pressure oil is supplied to big and small ends, with splash to all other moving parts. The oil pump includes a pressure relief bypass system with cartridge spin on filters (either single or duplex).

Points - Points are available for pressure switched or warning systems. Pressure lubrication can also be supplied to reciprocating crossheads.

Fluid Heads - All fluid pressure containing parts are constructed exclusively in AISI 316 stainless steel as standard equipment, regardless of size. Experience has shown that this is one area that should not have corners cut, or the assembly will corrode over time. The cost premium is far outweighed by the extended service life of the product. Some specific chemical applications can be met by the use of other materials such as aluminum bronze, duplex alloy stainless steels, hast alloy, titanium and high tensile 'plastics'.

Rams and packing - We have a large number of solutions to suit the application stuffing box conditions. Rams can be offered in a range of materials from ceramic to tungsten carbide. With a tailored ram material and coating operating against the latest packing materials we can expect extended service life.

Transmissions - All pumps in the range are designed with a 'bareshaft' format to allow for all types of transmission to be applied, giving a totally flexible output from the product. Low power sizes can be offered with multi V-belt or timing belt drives with chassis mounted or overhead electric motors (the pump crankcase is designed to accept the overhead concept where space is at a premium). For larger requirements a full range of helical and worm design gearboxes are offered for use with either electric motors or diesel engine prime movers.

Testing - Completed pumps and packages are fully works tested at duty point, regardless of size, and full NPSH tests are available from our own in-house test facility.

Paint Finishes - Single pack polyurethane paints are used as standard. However, many other systems approved paint systems are available in any choice of colour at an extra cost. Our sales team can supply further details.

High Integrity Sealing Systems - As the result of client and market pressures for increased health and safety requirements, Ram Pumps has engineered products to reduce potential leakage and emissions from our product range. This optional provision of high integrity sealing systems can be specified throughout the Ram Pumps product range. Subject to client requirements, these systems can have numerous facilities for leakage monitoring and detection. While plunger pumps have a reputation for excessive leakage to atmosphere, this is not the case with the sealing systems developed by Ram Pumps.